Our TruSense S300 series sensors use eye-safe lidar pulses to gather accurate level measurements on a wide variety of liquids, even clear water. Customizable programing and configuration options accommodate your application's needs.

Tell us about your application and measurement needs!

Tell us about your application and find out if an S300 series laser sensor is the right choice for your needs.

Laser sensors bring advantages to several different fields.

Contact-sensor alternatives invite exposure to various materials and often install at the bottom of large tanks. Meanwhile, non-contact sensors tend to be installed in easy-to-access areas that avoid material exposure.

Avoiding contact with materials means that our sensors perform longer.

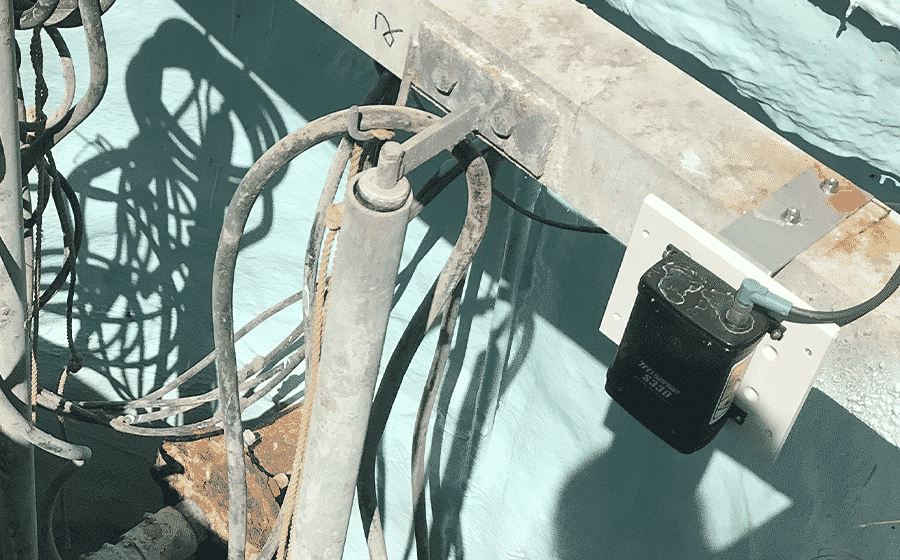

An S300 sensor installed at an easy-to-reach location.

Keeping a clean sensor is a best practice made easier by non-contact performance.

Contrary to contact sensors, our sensors are commonly located near or on a tank’s lid or hatch.

Easier-to-access locations complement worker safety.

Thanks to the easier access that our sensors tend to create, some safety hazards can be eliminated.

All of our non-contact, continuous measurement laser sensors offer high accuracy. In the general scope of applications, our Universal Laser Sensor’s (ULS) accuracy reigns supreme. However, our S300 series sensors are the better choice for industrial applications in liquid-level measurement, with typical accuracies of +/- 10 mm (.39 in) compared.

Lidar sensors can function in narrow environments.

Our time-of-flight laser sensors use lidar. Some alternatives use radar, which casts a relatively wide and diffused energy beam.

Some applications may require a more focused beam to overcome structural obstacles.

S300 Series Beam Divergence = 3 mrad (equal to 15 cm beam diameter @ 50 m or .5 ft @ 164 ft)

S300 Series Beam Divergence while using a Diffusing Lens = 44 mrad (equal to 220 cm beam diameter @ 50 m or 7.33 ft @ 164 ft)

S300 Sensors offer flexible configuration settings.

Flexibility in configuring a sensor for your specific application’s needs is key.